PIPELINE MONITORING

![]() Prevention of the environmental impact

Prevention of the environmental impact

![]() Reduction of the human risks

Reduction of the human risks

![]() Increase of the profitability

Increase of the profitability

![]()

![]()

![]()

An onshore or offshore pipe crosses tens or even hundreds of kilometers and can be exposed to many damages due to human or natural factors. To detect these risks, define them and provide the most adapted solution, a continuous monitoring all along the structure is needed to:

- check the integrity of the pipeline

- anticipate, detect and identify the threats and potential damages

- provide a quick and adapted reaction to the detected problems.

The FEBUS Optics solution allows to ensure a real-time and continuous monitoring of a pipeline integrity.

Operating onshore or offshore, the performances of the FEBUS distributed fiber optic sensing interrogators allow to enhance the asset sustainability.

Thanks to the quality of our distributed sensing patented technologies, of our embedded software FOPipe Suite and of the power of our detection and classification algorithms:

| Real-time information | Precise, reliable and repeatable data | Precise localization of the alerts | Intelligent alert detection |

- Anticipating and detecting leaks

PIPELINE INTEGRITY

- Localizing with precision, identifying the event and alerting in real-time

INTRUSION DETECTION

- Real-time monitoring of operational events

OPERATIONAL EVENTS

- Pipeline monitoring tests, demonstrations and trainings

TEST CENTER

LEAK PREVENTION AND DETECTION

Many environmental events can cause leaks: ground movements, hot-tap (intrusion), corrosion...

A continuous monitoring of the integrity of the structure is needed to preserve it from any damage that could have an environmental or human impact.

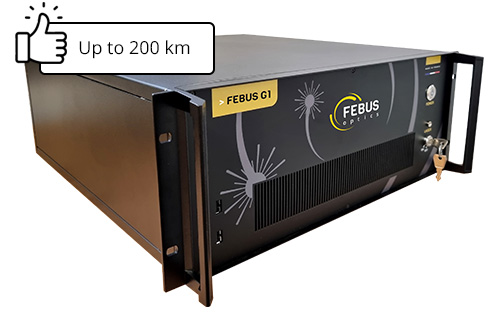

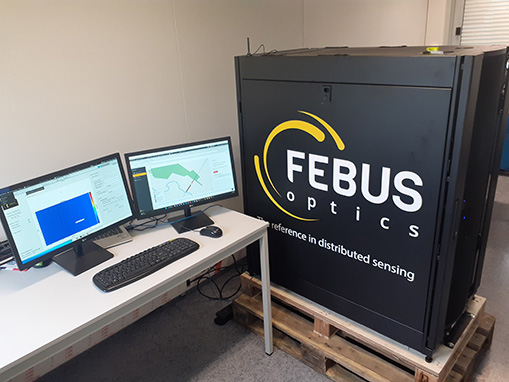

FEBUS Optics provides a complete solution to prevent and detect leaks on pipelines. The FEBUS G1-R (DTS - Distributed Temperature Sensing) is integrated to an entirely equipped cabinet. Our interrogator analyses the temperature all along the pipe. In case of a variation, the event is localized with an accuracy of one meter or more.

FEBUS cabinet entirely equipped for

the prevention and the detection of pipeline leaks

In case of a gas leak, a drop in temperature occurs (Jules Thomson effect). Thanks to the FEBUS G1 (DTS - Distributed Temperature Sensing) and to our patented technology, it is quickly detected. On the contrary, an increase in temperature is identified during a hot liquid leak (hydrocarbon for instance).

The abnormal thermal variations also allow to identify when an initially buried pipeline is uncovered or close to the surface (natural erosion, works).

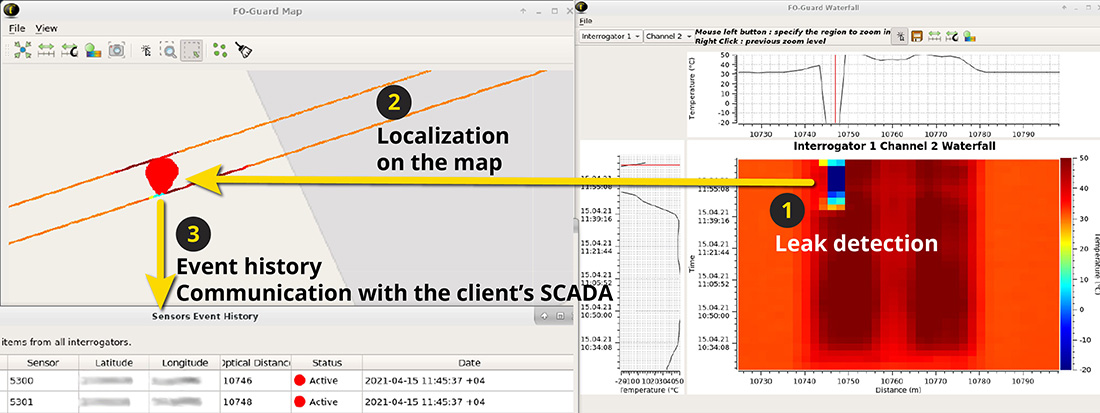

Gas leaks visualization, precise localization and alerting thanks to the FOPipe Suite software

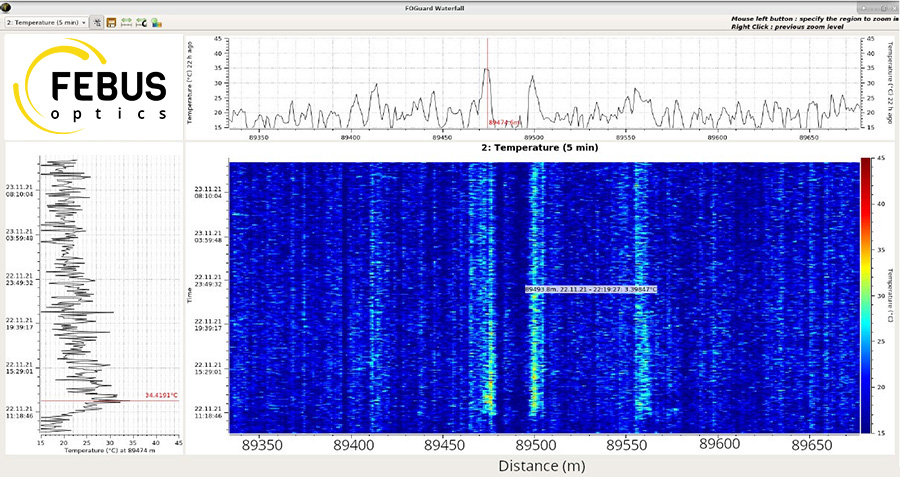

Not all leaks cause important temperature changes. The smallest ones only create very discreet variations.

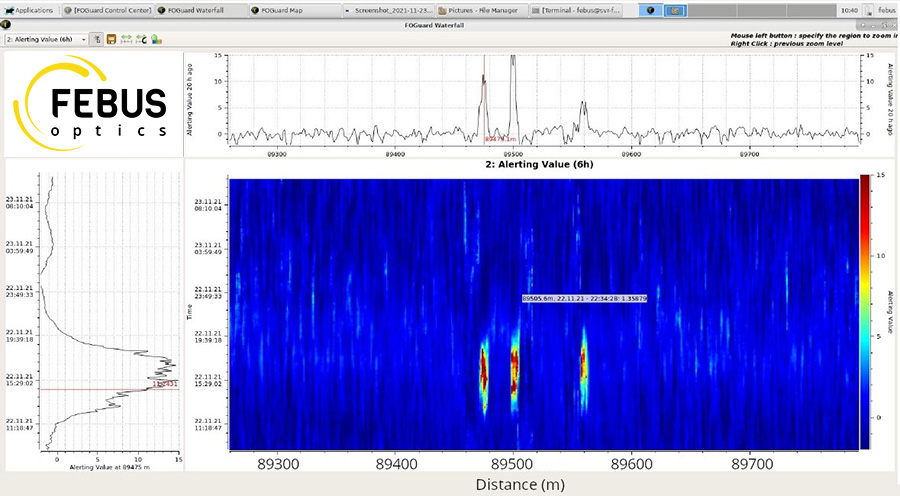

FEBUS has developed its own analytics algorithm to detect them: the RUSH (Real-Time analysis Using Signal History).

- Our algorithm simultaneously analyses temperature trends during different periods (examples: 5 minutes, 1 hour, 24 hours).

- Our technology identifies any abnormal variation compared to observed trends.

- It allows micro leaks to be detected over long periods of time by removing seasonal thermal effects.

Pipeline leak detection at 90 km from the interrogator

Instantaneous measurements

Demonstration achieved at the Sophie Germain Test Center.

RUSH algorithm integration:

- important reduction of the long distance noise

- increase of the sensitivity

- no false alarms

The FEBUS Optics solution can gather several algorithms to perform parallel analysis of the temperature data all along the pipeline, allowing the leaks detection system to be more robust.

INTRUSION DETECTION

Intentional or accidental third-parties intrusions can occur: excavator digging, product theft attempt...

The FEBUS A1 (DAS - Distributed Acoustic Sensing) achieves dynamic acoustic measurements. Its state-of-the-art sensitivity enables to detect the most discreet intrusions.

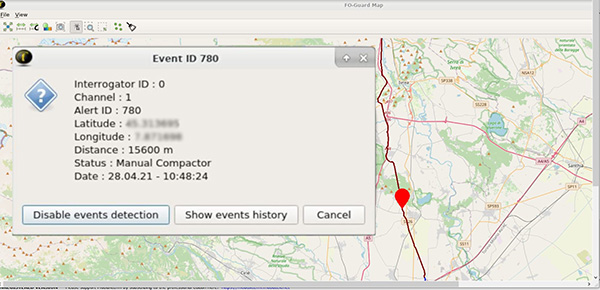

Precise localization, classification and alerting by FOPipe Suite following an intrusion on a pipeline

Fully equipped cabinet and FOPipe Suite sofware

for pipeline intrusion detection

Any movement creates an acoustic wave along the optical fiber that is instantaneously sensed by the FEBUS Optics interrogator. The trigger of the alarm is adjustable depending on the needs.

Our integrated software FOPipe Suite allows:

- a precise and real-time localization of the alerts

- a decrease of the false alerts

- an interoperability with the installed monitoring system.

Combining FOPipe Suite to our events recognition algorithm enables to identify them instantaneously. Our solution indicates the class of the alert: excavator, auger, hydraulic hammer, farm machine, leak...

During the implementation, the irrelevant classes for the project are defined to be ignored by our algorithm. This way, unnecessary alerts are avoided.

|

Intrusions detection |

Precise localization of the alerts | Events identification | Real-time alerting |

OPERATIONAL EVENT DETECTION

During the pipeline operation, events qualified as "operational" can occur and even be a threat for the integrity of the structure. They need to be monitored.

FEBUS technology detects different kinds of events:

- activity of operation rotary mechanical equipment (as a pump, a motor, a generator),

- water leak,

- deterioration of the structure, cracks for example,

- degradation of the valves due to their opening/closing repetition,

- generation of bubbles and pockets movements in the pipe,

- pig movements.

The pigging is the action to insert a "pig" in a pipe to clean it. Indeed, some sediment appears on the casing and it can affect its production. This operation needs to be monitored.

The FEBUS Optics distributed fiber optic sensing patented technology and our FEBUS A1 (DAS - Distributed Acoustic Sensing) enable a real-time tracking of the "pig" in the pipeline to:

- know its position and its speed

- predict the arrival of the tool at the end of the structure

- control the flow of oil or gas and to be sure that the "pig" is not damaged

- avoid uncontrolled releases at the end of the infrastructure

- limit human activity along the pipeline and to ensure the safety of the operation.

By following the "pig" progress through the structure, the risks of accidents or damages are reduced and production is optimized.

PIPELINE INTEGRITY MONITORING AT THE CESG

The CESG (Test Center Sophie Germain) is our tool to achieve tests to monitor pipeline integrity at a semi-industrial scale:

- leak detection

- intrusion detection

- geophysical risks prevention.

Our pipeline is 22 meters long. It is equipped with electrovalves to generate pressurized leaks in various configurations (sizes, orientations). The fiber optic cables are laid out in a trench in different configurations to find the best setup to detect an event as quickly as possible.

A hydraulic jack placed under the trench allows us to generate a pressure up to 30 tons to deform the structure and create ground movements.

FEBUS Optics devices are EC certified to simulate gas and hydrocarbon leaks and:

- they allow to create air leaks (50 bars)

- hot water leaks (60 °C, 20 bars)

- with different orientations (0 to 360 °)

- and with different sizes (1 to 6 millimeters).

Liquid leak on a pipe at the Test Center (CESG)

To best simulate on-site conditions, the FEBUS Optics technical experts perform leak tests inside the Test Center, simulating very long applications (up to 100 kilometers) thanks to spools of optical fiber.

The FEBUS teams offer real-size tests and demonstrations.

We specifically set up our pipeline (or the client's one) and the fiber optic cables according to the project features (one or several optical fibers, wrapped around the pipeline or placed against the structure, the pipeline buried or immersed, with or without any thermal isolation...).

The CESG is also a training center where the FEBUS Optics teams present our solutions and provide trainings to our clients. A practical phase of device usage in an experimental context and case studies are performed.

Theoretical and practical trainings and demonstrations

FEBUS OPTICS IMPLEMENTATION AND SERVICE

The FEBUS Optics solution offers high performance when a fiber grid is already installed. Nevertheless, we bring our expertise to optimize the optical fiber cable choice and its position on the pipeline.

We ensure the deployment of our pipeline monitoring solution and its setup on-site or remotely.

Then, we provide a support. After an operation period initially defined with the client, FEBUS experts verify the well-functioning of the system and optimize it.

Then, they ensure training and support throughout the project.

FEBUS Optics also offers yearly maintenance contract, warranty extension after 3 years and continuity of services.

WHY CHOOSE FEBUS OPTICS TO MONITOR THE PIPELINE INTEGRITY?

| State-of-the-art detection sensitivity (DAS and DTS technologies) | All threats are detected, non-relevant alerts are ignored and the production losses are limited. | |

| Real-time monitoring | A quick answer is provided, environmental and human risks are prevented. | |

|

Precise localization Alert qualification |

The maintenance costs are optimized. | |

|

Continuous monitoring |

A control is done to be sure that the problem is solved and a new intervention is planned if needed. | |

|

Long range |

All distances are achieved, optimizing this way CAPEX and OPEX. |

| Communication of the alerting software via standard protocols | Our solution is fully compatible with any hypervisor. | |

|

Maintenance contract |

FEBUS' devices availability is optimized. | |

|

FEBUS Optics support |

The project runs in an atmosphere of serenity. |

|

| ISO 9001 certification | The quality of our products, services and support is recognized. | |

| Possibility to try our solution in the Test Center (CESG) | Our solution is validated to answer to your project's needs and specificities. |

You are looking for a solution to prevent pipelines against potential damages?

Any questions?