CABLE MONITORING

![]() Maintenance costs reduction

Maintenance costs reduction

![]() On-site time optimization

On-site time optimization

![]() Environmental impact reduction

Environmental impact reduction

![]()

![]()

![]()

![]()

The cable monitoring allows to:

- monitor the correct functioning of buried or submerged umbilical and power cables

- anticipate their failures

- provide a quick and adapted response to the detected problems

FEBUS devices use a single-mode optical fiber already laid in the cable. Based on an OTDR (Optical Time Domain Reflectometry) technology, FEBUS devices only need to be plugged to a single end of the fiber. This way, they provide an easy implementation, a very long range and a cut-immunity.

Using Rayleigh (DAS - Distributed Acoustic Sensing) and Brillouin (DTS - Distributed Temperature Sensing) technologies, accurate, reliable and precisely localized data is obtained.

A continuous monitoring along the cables is ensured.

- Control of the temperature with the FEBUS G1-R

- Detection of any default with the FEBUS A1

- Increase the range of FEBUS interrogators and optimization of the investments thanks to the FEBUS REM (Range Extension Module)

- Detection and precise localization of an unusual increase of the temperature, optimization of the cable use thanks to the RTTR software

HOT SPOT DETECTION

- Detection and provision of quick intervention thanks to real-time alert accurately localized

DEFAULTS AND SHOCKS

- Detection and localization of the cable movement zones (dug-up parts), continuous monitoring of the riskiest segments

SUSPENSION ZONES

- Detection and accurate localization of the event for a quick response

PARTIAL DISCHARGES

HOT SPOT DETECTION

The FEBUS G1 (DTS - Brillouin) allows to detect hot spots along the cable.

The emergence of a hot spot is a major sign of failure that requires an immediate intervention. To give the fastest response, the FEBUS G1 and its integrated software FEBUS FOGrid Suite provide real-time, distributed, continuous and localized data with high accuracy thanks to measurements every 10 centimeters.

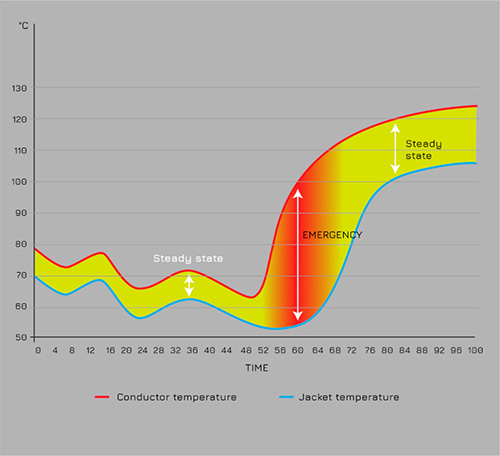

The RTTR software can be combined to the cable monitoring. With this advanced modelling tool, the temperature of the conductor is defined from the fiber temperature.

The Real-Time Thermal Rating software or Dynamic Cable Rating (DCR) links the temperature of the optical fiber to the electrical load flowing through the cable. It makes a correlation between different data such as the load history it has recorded or the ambient thermal conditions.

Providing continuous monitoring of cables with the FEBUS G1, the RTTR software allows the prediction of the time needed for the cable to reach a temperature. The maximum load that can be supported before reaching a critical threshold is also defined.

This way, it is possible to optimize the use of the cable, to prevent situations that will require intervention and to identify alerting thresholds.

The FEBUS G1-R is the rackable version to be integrated to a computer cabinet.

The FEBUS G1-C is the portable version. Compact, equipped with wheels and completely autonomous, it can be taken everywhere and allows to operate fast and easy measurements.

The RTTR software allows to

- reduce the risks of cable faults,

- secure the transmission system,

- maximize its reliability,

- offer a quick response depending on the nature and level of the alert.

DEFAULTS AND SHOCKS

Cables are commonly implemented for more than 40 years of activity. They have to deal with various disturbances: impact of seasons on the humidity level of the soil, ground movements, development of trees roots, moulds, abrupt increase in production needs, etc...

|

Distributed, real-time and continuous data |

Precise localization of the alerts | State-of-the-art sensibility: 3 pε/√Hz |

To monitor the cable integrity, the FEBUS A1 (DAS) allows:

- to detect every default along the cable

- to be alerted

- to localize it with precision.

This way, the efficiency of the interventions is increased. Our FOGrid Suite software is also integrated in the FEBUS A1.

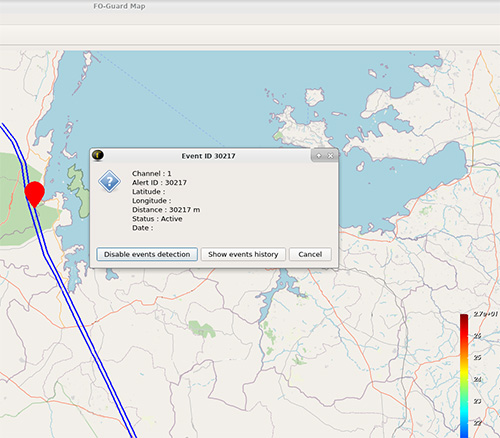

Precise localization of the alert on the FOGrid Suite (FEBUS software) map

SUSPENSION ZONES

THE FEBUS A1 (DAS) PROVIDE REAL-TIME DETECTION OF EVERY MOVEMENT ALONG THE CABLES, EVEN THE TINIEST ONE.

Onshore umbilical and power cables are mainly used to supply bottom fixed and floating wind farms for the production of Marine Renewable Energy (MRE).

By detecting a movement in the optical fiber, the suspension zones are identified: dug-up cable segments, crossing of a crevasse (free span)...

Cable movements damage it more quickly. As the cable is more subjected to failure, a continuous monitoring of the asset is therefore needed.

The FEBUS A1 (DAS - Distributed Acoustic Sensing) interrogators provide:

- real-time alert of the emergence of weakness zones in the infrastructure

- precise localization of the events.

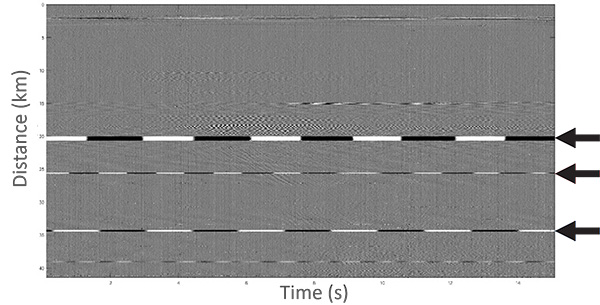

Real-time visualization of monitored cable oscillations with the FEBUS A1

In order to facilitate their maintenance, the FEBUS Optics interrogators can be placed onshore, away from the wind farm. Easy to reach, the maintenance expenses are reduced as there is no need for specialized personnel to intervene offshore.

The responsiveness of the interventions is also increased with

- a measurement sample every 20 centimeters

- a precise map vizualisation of the alerts thanks to our integrated software FEBUS FOGrid Suite.

Suspension zones of the observed cable at three different locations

PARTIAL DISCHARGES

Partial discharges endanger the cable insulation by accelerating its deterioration.

Since the charge released is very small, not all the interrogators have the necessary performance to detect it. The FEBUS A1 (DAS) provides state-of-the-art performances with a very high sensitivity of around 3 pε/√Hz.

It thus enables to ensure a continuous and meticulous cables monitoring. A real-time notification is sent as soon as partial discharges are detected along the cable. It is also precisely localized on a map generated by the FOGrid Suite software.

The FEBUS A1 can monitor up to 50 kilometers of cable and the FEBUS G1, up to 100 kilometers.

To increase their range, FEBUS interrogators can be associated to the FEBUS REM (Range Extension Module). Thus the entire asset is monitored for a minimal cost and the maintenance expenses are optimized.

FEBUS OPTICS IMPLEMENTATION AND SERVICE

FEBUS technical leads come on-site to install our dedicated solutions on or in the infrastructures.

They entirely ensure their implementation and provide operational solutions adapted to all the project specificities.

- Checking of the integrity of fiber optic cables

- Calibration of our solution on the infrastructure

- Validation of the global monitoring system and adjustments

- Training

They provide support during the lifetime of our solutions on the infrastructure: support for the data interpretation, adjustment of measurement parameters...

FEBUS Optics also offers yearly maintenance contract, warranty extension after 3 years and continuity of services. Spare parts, backup machines, on-site repairs are optionally provided. Our technical leads present a prevention plan adapted to the client's needs.

WHY CHOOSE FEBUS OPTICS TO MONITOR THE CABLE INTEGRITY?

| State-of-the-art detection sensitivity (DAS, DTS, DSS technologies) | All threats are detected, non-relevant alerts are ignored and the production losses are limited. | |

| Real-time monitoring | A quick response is provided. | |

|

Precise localization Alert qualification |

The maintenance costs are optimized. | |

|

Long range |

All distances are achieved, optimizing this way CAPEX and OPEX. |

| Communication of the alerting software via standard protocols | Our solution is fully compatible with any hypervisor. | |

|

Maintenance contract |

FEBUS' devices availability is optimized. | |

|

FEBUS Optics support |

The project runs in an atmosphere of serenity. |

|

| ISO 9001 certification | The quality of our products, services and support is recognized. |

FEBUS Optics is a partner in the AFLOWT project to work on a new technology of Floating Offshore Wind (FOW) turbines at competitive costs. The aim is to demonstrate its performance and sustainability.

You want to prevent your umbilical and power cables against potential damages?

Any questions?