Our Test Center (CESG)

A ONE-OF-A-KIND TEST AND SIMULATION TOOL FOR:

![]() pipeline monitoring

pipeline monitoring

![]() perimeter security and third part intrusion

perimeter security and third part intrusion

![]() power cables

power cables

![]() ground movement

ground movement

![]() all infrastructures monitoring/SHM

all infrastructures monitoring/SHM

![]()

![]()

![]()

![]()

Innovating, testing and validating of our solutions is our priority.

FEBUS Optics has its own test center of 455 Sqm on a land of 2 500 Sqm entirely dedicated to

- Prevent, detect and localize at an early stage leaks (liquid and/or gas), intrusions and ground movement

PIPELINE INTEGRITY

- Identify an intrusion attempt, localize it, define its nature

PERIMETER SECURITY

- Detect hot spots, defaults, including partial discharges

CABLE INTEGRITY

- Testing of fiber optics cables, pipe in pipes, concrete structures...

TESTS AND QUALIFICATION

- From optical fiber to distributed sensing: working principle, applications, case studies, use of the DAS, DTS, DSS interrogators (2 or 3 days)

TRAINING

PIPELINE INTEGRITY

Pipeline instrumentation in our Test Center

A 25 meters long trench is at our disposal in our Test Center. With a height and width of 1.50 meters, it is isolated from vibrations and can receive pipelines of diameters up to 10 inches.

Depending on the needs, the pipeline can be uncovered, buried or submerged.

The trench can be equipped with fiber optics cables fitting the site conditions:

- type of cable (telecom, dedicated, enhanced...),

- installation (direct buried or inside a duct),

- at the right position (above, on the side or beneath the pipeline).

Liquid leak (5 mm) on a buried pipeline in our Test Center

Leaks can be created and controlled:

- the pipe can be pressurised with air (< 50 bars) and hot water (< 20 bars, < 60 °C)

- 3 leak orientations are available: top, side and bottom (12, 3 and 6 o'clock)

- 3 leak sizes are available for each position: 1, 3 and 5 mm holes, controlled on demand thanks to electrovalves.

Very long assets of up to 100 kms can be simulated inside our Test Center (CESG) by using dummy fiber connected before the installation.

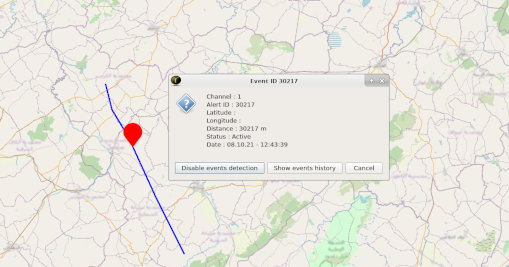

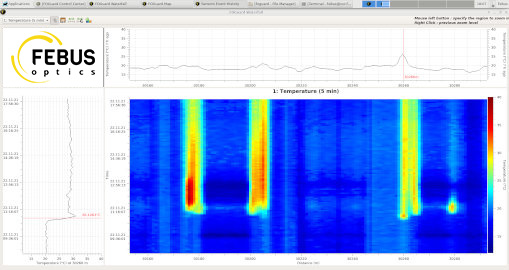

Leak detection: alerts with our software FOPipe Suite

Leak detection: waterfall with our software FOPipe Suite

A hydraulic jack placed under the trench allows us to generate a pressure up to 30 tons to simulate ground movements.

Thanks to this setup, our Test Center CESG can offer a complete tool for optimization, innovation and real scale testing of our pipeline integrity monitoring solutions.

We can also test various fiber optic installation configurations and define their specifications.

PERIMETER SECURITY

The fence of our Test Center is equipped with fiber optic cables to test and validate different kinds of deployment. They are placed in various configurations: horizontally, diagonally, on a straight line, curved and buried.

Using this asset, FEBUS Optics research and development teams freely perform all kind of tests to continue improving of our perimeter protection solution.

On demand, we can organize a presentation/demonstration of our solution: discover our distributed fiber optic sensing solution for your intrusion detection and perimeter security needs.

Our algorithms of event recognition and precise localization are based on different methods (Machine Learning, nearest-neighbor imputation...) and are adapted to your application.

POWER CABLE AND UMBILICAL INTEGRITY

The FEBUS Optics Test Center is the perfect tool to test, design and verify power cable and umbilical integrity monitoring.

Its large surface area allows us to drive representative scale experimentations.

Cable resistance can be tested on demand. They are subjected to bending, tension and twist to record their behavior. They can also be subjected to high temperature environment using a climate chamber to verify aging and distributed temperature sensing performances. We create and test various set-up protocols according to the specificities of each installation configuration. Thank to our expertise, some recommendations can be given concerning the choice of cables and on how to implement them inside.

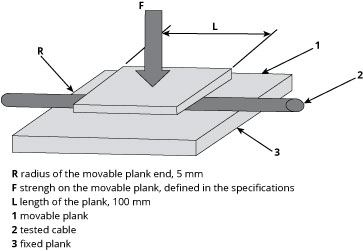

Cable strain resistance test in our Test Center

WIDE RANGE OF TESTS AND QUALIFICATION CAPACITY

MECHANICAL AND ENVIRONMENTAL QUALIFICATION OF FIBER OPTIC CABLES FOR DISTRIBUTED SENSING

To ensure reliable and accurate measurements during your project, choosing the optical fiber cables most adapted to your needs is essential.

Our Test Center assesses the possibilities and the limits of different cables by achieving mechanical and environmental tests.

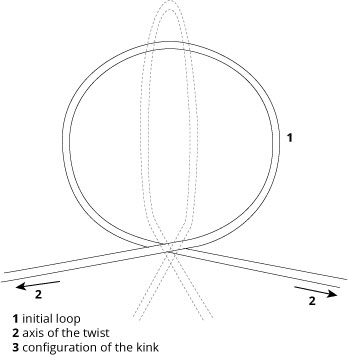

The cables are stretched, bended, crushed, kinked. A climatic chamber allows us to operate big and fast temperature changes.

Cable crush test in our Test Center

Cable kink test in our Test Center

Crush test of a junction box in our Test Center

Temperature test with a climatic chamber in our Test Center

The junction boxes of the fiber optic cables can also be tested. Thus we can qualify a complete system: interrogator - cable - junction box. Tests are achieved with different cable lengths, junction boxes can be submerged, and shocks and vibrations resistance are measured.

To provide the best solution to our clients, our complete offers are tested and validated in our unique Test Center to simulate conditions representative of real operating conditions:

- From the field (trench, fence...),

where the fiber optic cables are deployed,

- To the control room,

where the FEBUS interrogators and softwares are implemented.

Fully equipped cabinet in the FEBUS Optics Test Center

CUSTOM-MADE EXPERIMENTATIONS AND TRAININGS

Before choosing a long-term solution, you need to be sure it will answer your expectations within the conditions of the environment in which it will operate.

Each project is unique and presents its own specificities.

At your request, we can run many experimentations in our Test Center in similar or identical conditions as on-site. Doing so, you are sure our technology is efficient and reliable to answer your needs.

Following your clear instructions, we recreate the conditions in our installation and propose a set-up. We can also develop an implementation protocol according to your constraints, as to propose you an innovative and adapted response. This way, we qualify our interrogators and our solutions in our Test Center according to the specificities of your project.

Trainings are organized in our Test Center, on our interrogators and their applications, as well as on the distributed sensing technologies themselves.

From two to three days depending on your needs, we offer training to teach the functioning principle of distributed fiber optic sensing and to present its different applications. A practical phase of device usage in an experimental context and case studies are also planned.

Contact us to participate in the next training session or for a tailor-made program.

Need more information about our Test Center, the FEBUS Optics devices and solutions?