Well Monitoring

![]() Production optimization

Production optimization

![]() Workover optimization

Workover optimization

![]() Environmental and human risks reduction

Environmental and human risks reduction

![]()

![]()

![]()

(Carbon Capture Usage & Storage)

![]()

The monitoring of a well is needed to:

- look at the reservoirs dynamics and to optimize their production (flow profiling)

- provide a quick and efficient response to the failures observed on the completion parts, the tubings/casings and detect leaks

- monitor operations such as stimulation or hydraulic fracturation

- monitor the levels of the products stored in salt caverns or geological reservoirs.

Our patented technology of distributed fiber optic sensing offers major advantages over traditional methods.

The FEBUS Optics interrogators have been developed and optimized to meet all the challenges of well monitoring and its many applications. Our embedded softwares (on our DAS, DTS, DSS) provide all the tools required to the data processing and are easily implemented in any third-party solutions (hardware or software implementation). The fiber optic cable can be permanently deployed during the well completion or temporarily via wireline or slickline.

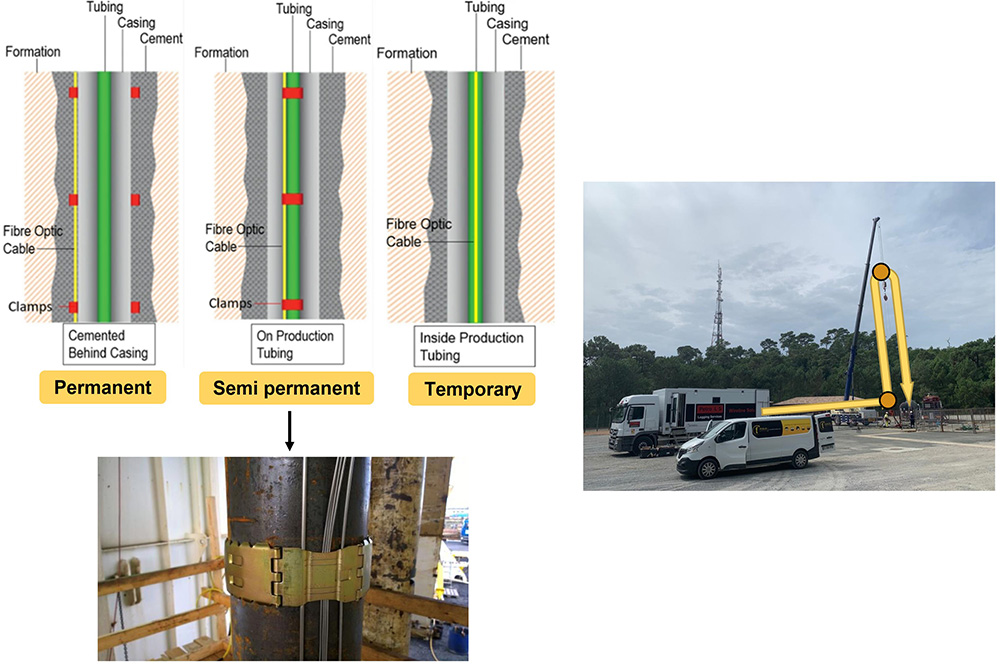

Permanent, semi permanent or temporary installation of the optical fiber by our partners

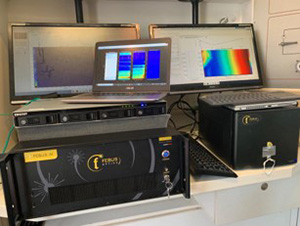

On the left, the FEBUS A1 (DAS) and on the right the FEBUS T1-R (DTS) in the control room

for a real-time monitoring

The fiber optic sensing is a non-intrusive method that allows to optimize the monitoring and maintenance costs of the well. It also provides:

- acoustic information with the FEBUS A1 (DAS - Distributed Acoustic Sensing) like the "Noise Logging Tool"

- temperature data with the FEBUS T1-R (DTS - Distributed Temperature Sensing)

- strain information with the FEBUS G1-R (DSTS - Distributed Strain and Temperature Sensing)

Distributed, continuous and real-time data are obtained along the well.

The gauge length is also adaptable before and after the operation on the FEBUS A1 (DAS - Distributed Acoustic Sensing).

- Characterize production and injection flows profiles, optimize extraction operations ("artificial lift"), flow profiling

PRODUCTION OPTIMIZATION

- Detect leaks on tubing/casing and any damages on the completion

WELL INTEGRITY

- Increase the production of the geothermal wells, regulate it, detect in real-time the induced seismicity risks

GEOTHERMY

- VSP acquisitions, local seismicity

SEISMIC ON WELL

- Liquid/gas and liquid/liquid interfaces monitoring

SUBSURFACE STORAGE

- Control of the fractures opening/closing and measurement of their width, cross-well monitoring

HYDRAULIC FRACTURING

PRODUCTION OPTIMIZATION

Analyzing the dynamics of the reservoirs to regulate their production and to anticipate their behaviour during the operation.

The production and injection profiles are defined with the FEBUS A1 (DAS - Distributed Acoustic Sensing) and the FEBUS T1-R (DTS - Distributed Temperature Sensing).

Onshore or offshore acquisitions provide:

- real-time information

- distributed data (adaptable number of measuring points and interval)

- understandable directly on-site

- and during all the lifetime of the well operation.

Without interrupting the production, several information are seen among other things:

- the flow intensity of the perforations level allowing to identify the best production or injection zones

- the warm-back effects

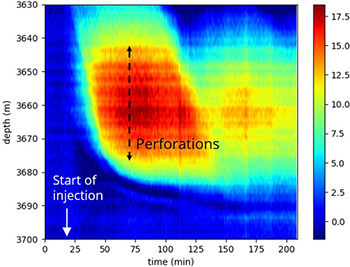

Stimulation of a perfored interval by injecting hot water and estimation of the required time to come back to the thermal balance ("warm-back") with the FEBUS T1-R (DTS)

A combination of FEBUS DAS and DTS technologies can be made for a better characterization of a reservoir via an accurate analysis of the data at the perforations level.

WELL INTEGRITY

Any failure on a well can have severe consequences on the environment and on the well productivity.

| Combination of the FEBUS A1 (DAS), the FEBUS T1-R (DTS) and the FEBUS G1-R (DSTS): a complete well integrity monitoring system |

||

|

FEBUS T1-R |

FEBUS G1-R |

|

A complete well integrity monitoring system is created by combining the FEBUS A1 (DAS), the FEBUS T1-R (DTS) and the FEBUS G1-R (DSTS).

- Our solution offers highly sensitive devices, distributed and real-time data.

- Any failure on the tubings/casings or on any part of the completion that could affect the productivity of your operation and have a significant environmental impact is detected.

- Alerts in case of damage on the completion are instantaneously sent.

- A quick and adapted response can be organized.

Among other things, FEBUS Optics solution allows to detect:

- leaks on the completion

Coupling of DAS/DTS sensing for the detection of leaks on tubing with the FEBUS A1 and the FEBUS T1-R

- leaks behind the casing

Leak detection on packer and precise localization (± 1 m) with the FEBUS A1

- a deformation/damage of the casing

| A higher reactivity to any anomaly on the completion |

Workover optimization | Increase of the profits |

Prevention against the environmental |

GEOTHERMY

One of the main challenges of our time is to sustain the environmental effort and to develop the renewable energies. Converting the heat of the subsurface geothermal energy in electricity is an answer to these goals.

The FEBUS A1 (DAS - Distributed Acoustic Sensing) provides a state-of-the-art acoustic sensibility and a very large range of frequencies.

The distributed fiber optic acoustic sensing is easy to deploy and significantly less expensive than traditional methods.

The EGS (Enhanced Geothermal System) can generate variations in temperature, pressure and induced seismicity. It is therefore essential to ensure continuous, real-time monitoring of the well and its environment by deploying a fiber optic cable in the well.

The FEBUS T1-R (DTS - Distributed Temperature Sensing) is Raman scattering to identify temperature changes in the well depth.

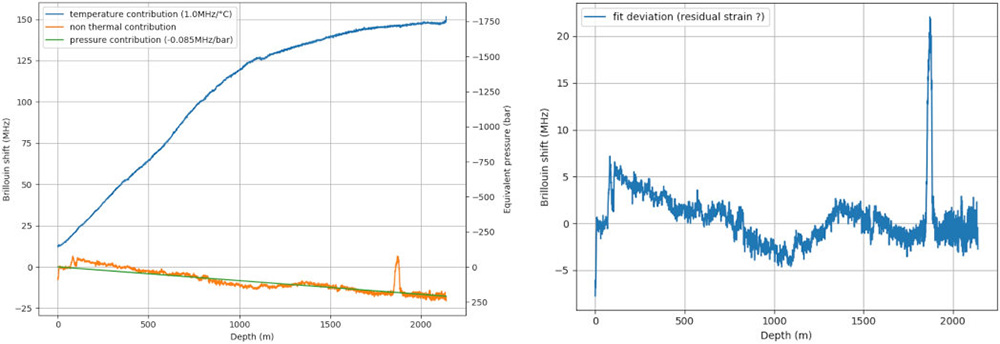

The FEBUS G1-R (DSS - Distributed Strain Sensing), based on Brillouin technology, detects the strain variations. This allows to verify that the cable is correctly positioned in the well and to control its integrity throughout the operation.

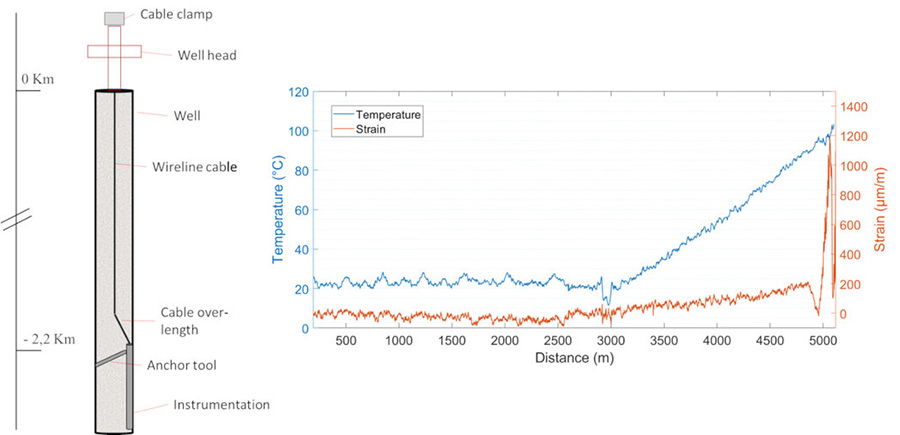

Fiber optic cable temperature and strain sensing along a well

Induced seismicity can be generated by geothermal production.

The FEBUS A1 (DAS - Distributed Acoustic Sensing) provides a real-time detection of any seismic activity produced by the reservoir operation. It makes possible to organize a rapid response and to regulate the production.

By using several optical fibers of a unique cable:

- the monitoring of induced seismicity is combined to the environmental properties changes due to the geothermal reservoir production (DAS + DTS + DSS)

- the distributed fiber optic measurement takes benefit from an easy deployment

- the deployment costs are optimized.

Fiber optic cable deployment in a well

Measurement of the pressure gradient of a geothermal well with the FEBUS G1-R 7 months after the deployment of the fiber

Thanks to very high resolution data, the production of the geothermal well and its security increase by preventing any environmental impact.

SEISMIC ON WELL

The FEBUS A1 (DAS) can be used to perform VSP (Vertical Seismic Profile) campaigns.

Our interrogator provides state-of-the-art sensitivity, distributed, continuous and real-time data for seismic acquisitions.

SUBSURFACE STORAGE

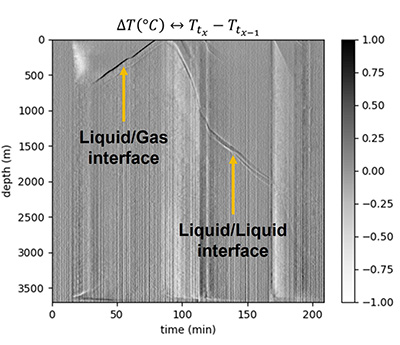

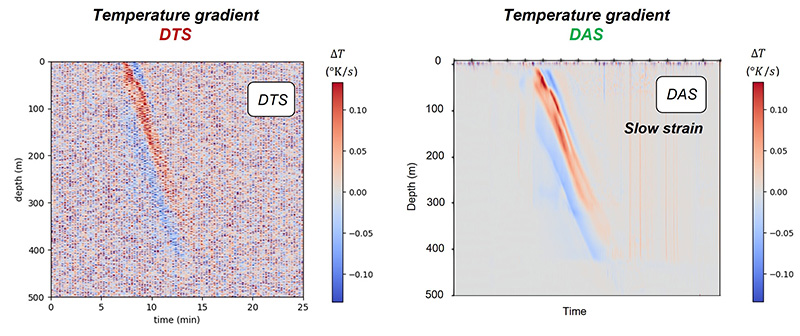

Acoustic data performed with the FEBUS A1 (DAS - Distributed Acoustic Sensing) and temperature data with the FEBUS T1-R (DTS - Distributed Temperature Sensing), allow to:

- identify liquid/gas and liquid/liquid interfaces using DTS measurements in case of quick dynamics

Localization of the liquid/gas and liquid/liquid interfaces with the FEBUS T1-R

- use "slow strain" data (FEBUS A1 - DAS) to estimate slower dynamics

Monitoring of the temperature changes with the FEBUS T1-R (DTS) and the FEBUS A1 (DAS)

thanks to "slow strain" measurements

Distributed and real-time measurements are achieved to optimize the subsurface storage operation.

HYDRAULIC FRACTURING

The FEBUS A1 (DAS) interrogator allows to monitor and secure the hydraulic fracking operations. Then it is possible to check:

- that the fractures are open enough to facilitate fluid extraction

- that undesirable secondary cracks do not occur

- that the proppant, injected to prevent the fractures from closing, is stable and to detect any backflow into the well

- that the cracks do not reach the surrounding control wells, creating cross-well interferences.

The integrity of the infrastructure is monitored, its production is optimized and the environmental risks caused by the activity are prevented.

FEBUS OPTICS IMPLEMENTATION AND SERVICE

The interrogators FEBUS Optics offer state-of-the-art performances.

FEBUS also provides a complete service of well monitoring.

- Our technical leads come on site to implement our solution. We can also operate in remote.

- We take care of the entire system configuration.

- We provide support for the entire service life of our solution.

FEBUS Optics offers yearly maintenance contract, warranty extension after 3 years, continuity of services. Spare parts, backup machines, on-site repairs are optionally provided. Our technical lead presents a prevention plan adapted to the client's needs.

WHY CHOOSE FEBUS OPTICS TO MONITOR A WELL?

| Very high quality (performances and metrology) of the devices and software (DAS, DTS, DSS technologies) | All the failures are detected, the production losses and the environmental and human risks are limited. | |

| A continuous improvement of our devices and services | Our solution provides state-of-the-art tools and the best support for any project. | |

|

Ergonomic equipment and softwares |

Learning how to use our solutions is easy. | |

|

Non-intrusive method |

A well monitoring is ensured without losing any productivity. | |

|

Distributed measurements |

The data can be exploited all along the well. |

| Real-time monitoring | A response is run very quickly. | |

|

Durability of the equipment (optical fiber & interrogator) |

The maintenance costs are optimized. | |

|

Communication of the software via standard protocols |

Our solution is fully compatible with any hypervisor. |

|

| Maintenance contract | FEBUS' devices availability is optimized. | |

| FEBUS Optics support | The project runs in an atmosphere of serenity. | |

| ISO 9001 certification | The quality of our products, services and support is recognized. |

Looking for a well monitoring solution to optimize the production and prevent the environmental and human risks?

Any questions?