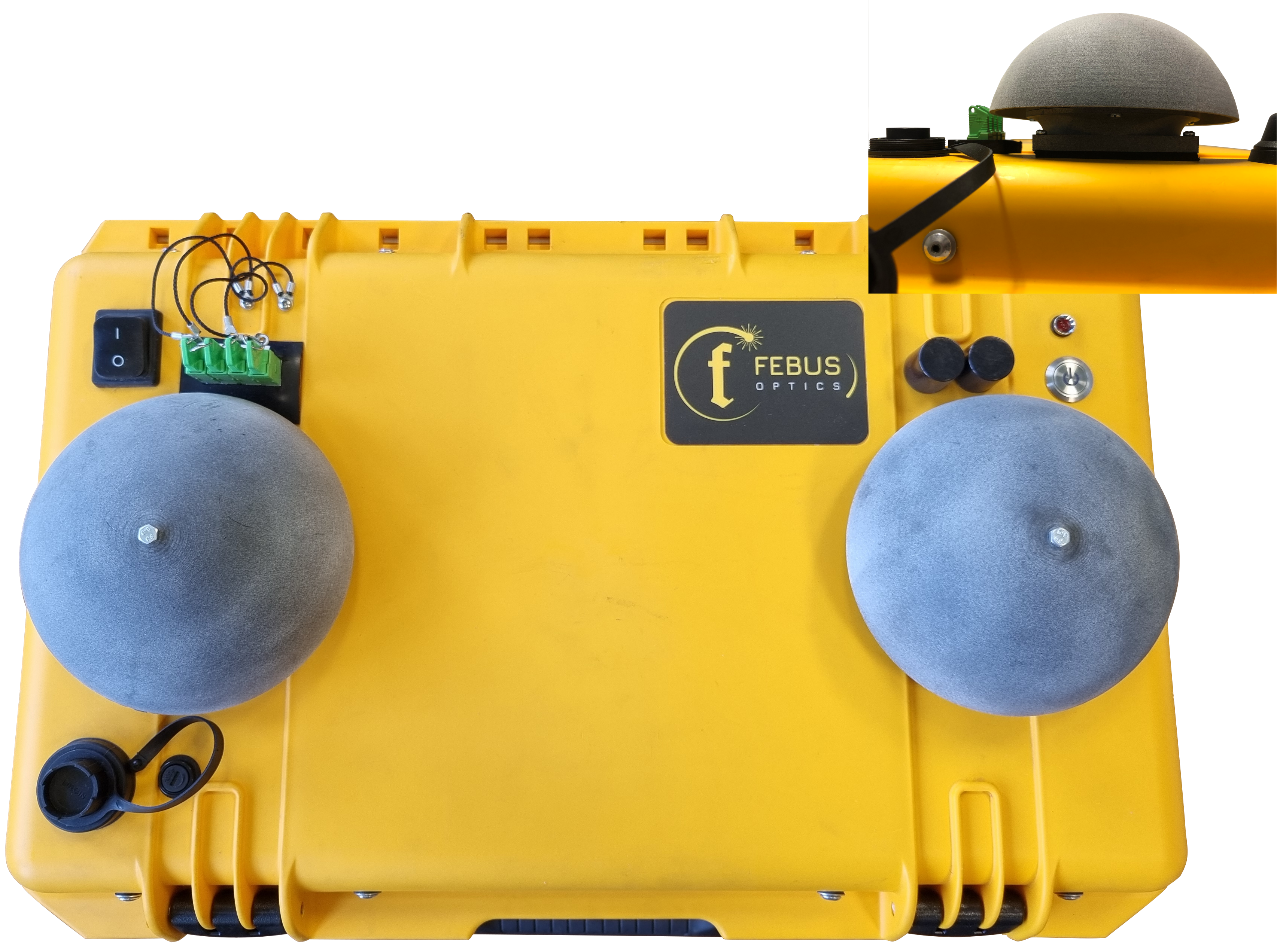

The FEBUS Optics’ G1-C has been designed to provide quick and easy distributed temperature and strain sensing (DTS & DSS) for easy transportation and mobility.

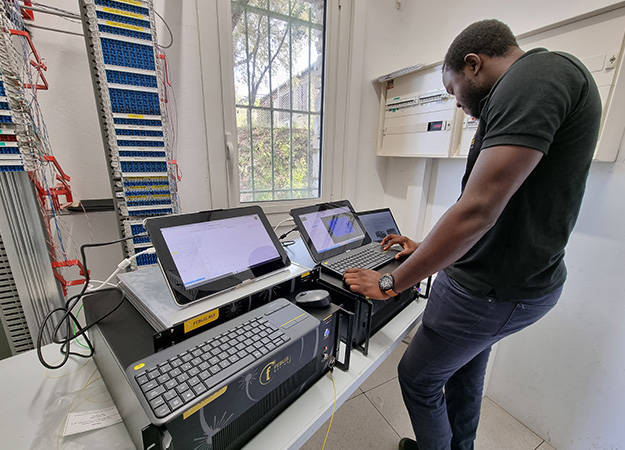

Requiring only a single-ended connection, the device needs an optical fiber deployed on the infrastructure to operate. Compact, autonomous and extremely fast (up to 1 Hz), the FEBUS G1-C allows to acquire strain and temperature information along several tens of kilometers wherever it is needed. The device is also optimized to run in harsh conditions.

The FEBUS G1-C is easy to implement and to integrate into any supervision system.

The solution for DSS and DTS needs with high mobility

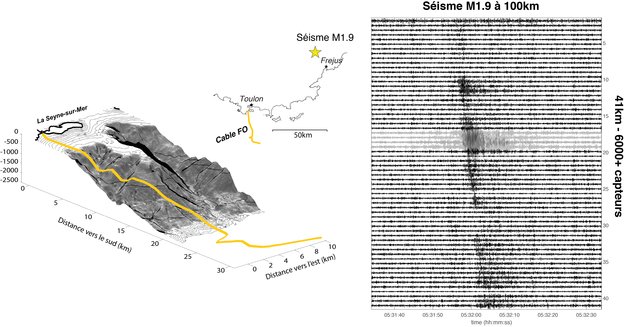

Thanks to the distributed fiber optic sensing technology, the user performs a real-time measurement and collects localized, accurate and reliable data.

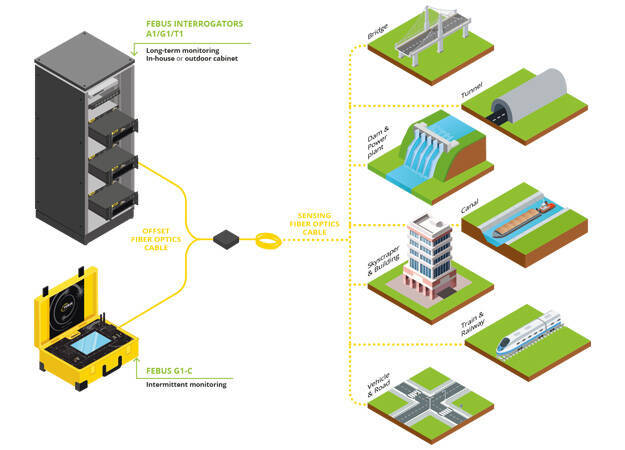

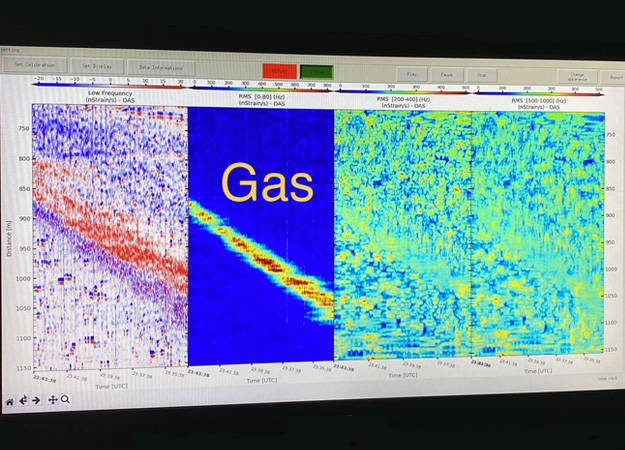

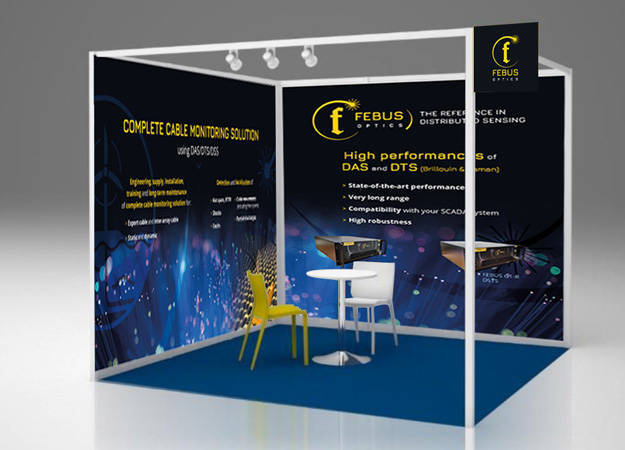

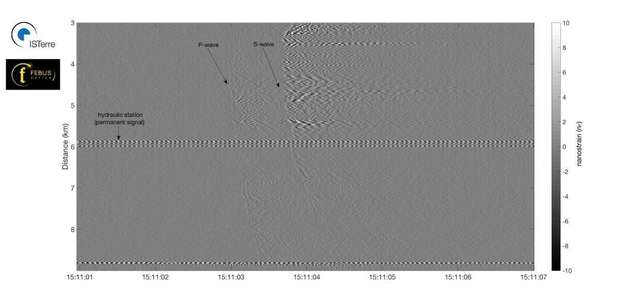

Using Brillouin optical time-domain reflectometry (B-OTDR), the FEBUS G1-C provides strain and temperature measurements for various applications:

- pipeline monitoring: gas and water leak detection, integrity monitoring;

- ground monitoring: ground movement, soil water content monitoring;

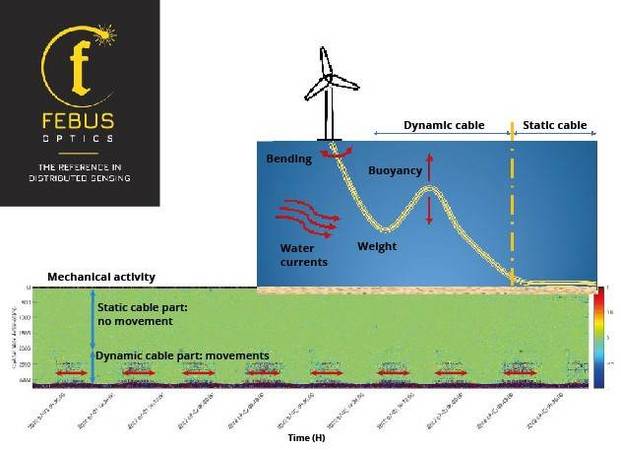

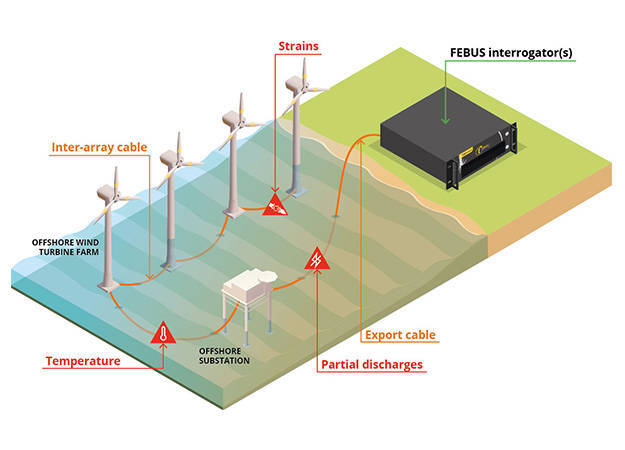

- power cable and umbilical monitoring: hot-spot detection, integrity monitoring;

- well monitoring: temperature profile, leak detection, interface detection, casing integrity monitoring;

- Structural Health Monitoring (SHM): ground movement, stress monitoring.

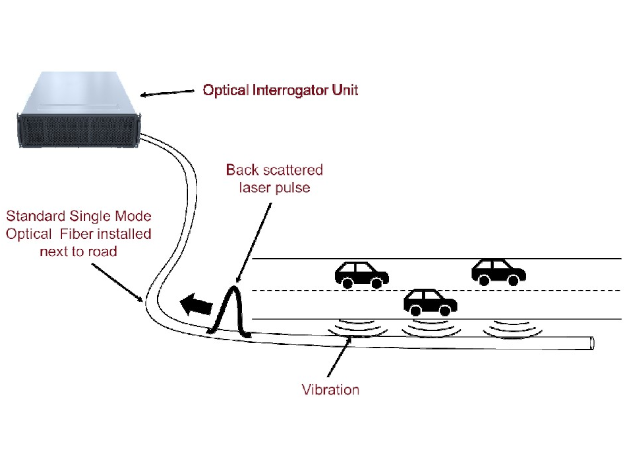

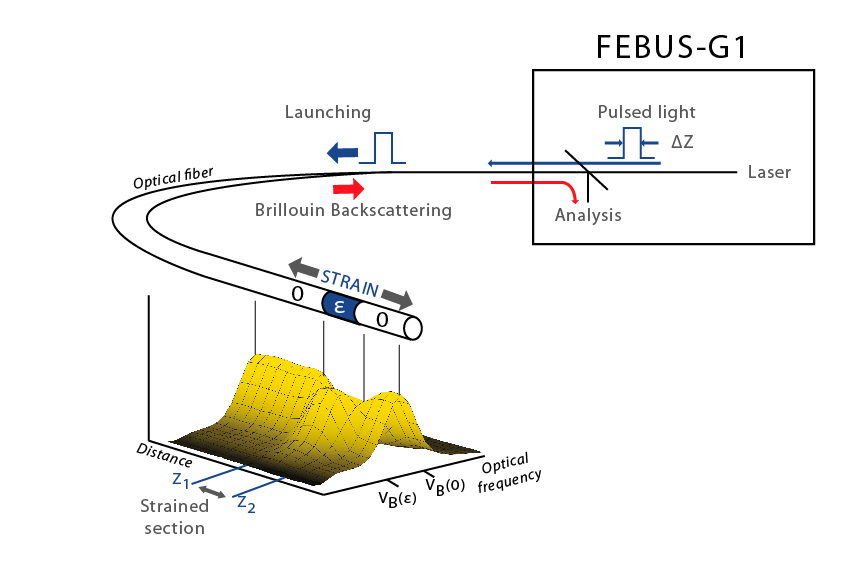

How does Brillouin distributed fiber optic sensing work?

|

When light propagates along an optical fiber, a small amount of the carried energy backwards in the cable with a shifted wavelength. It is called Brillouin Shift. The shift is temperature and strain dependent. Detecting the changes allows to measure both parameters. Furthermore, to locate the measurements, we look at the scattering time. When a pulsed light propagates along the fiber optic cable, Brillouin scattering occurs at any one point exactly when the pulse reaches that point. As light velocity is perfectly known in the fiber, the exact location of each scattering point can be determined. |

|

The FEBUS G1-C key features

The FEBUS G1-C offers unique feature to achieve strain and temperature distributed fiber optic sensing with high mobility.

Portable and compact, our interrogator only weights 15 kg. Furthermore, it is equipped with wheels. Therefore, it can easily move and perform acquisitions wherever it is needed.

|

|

|

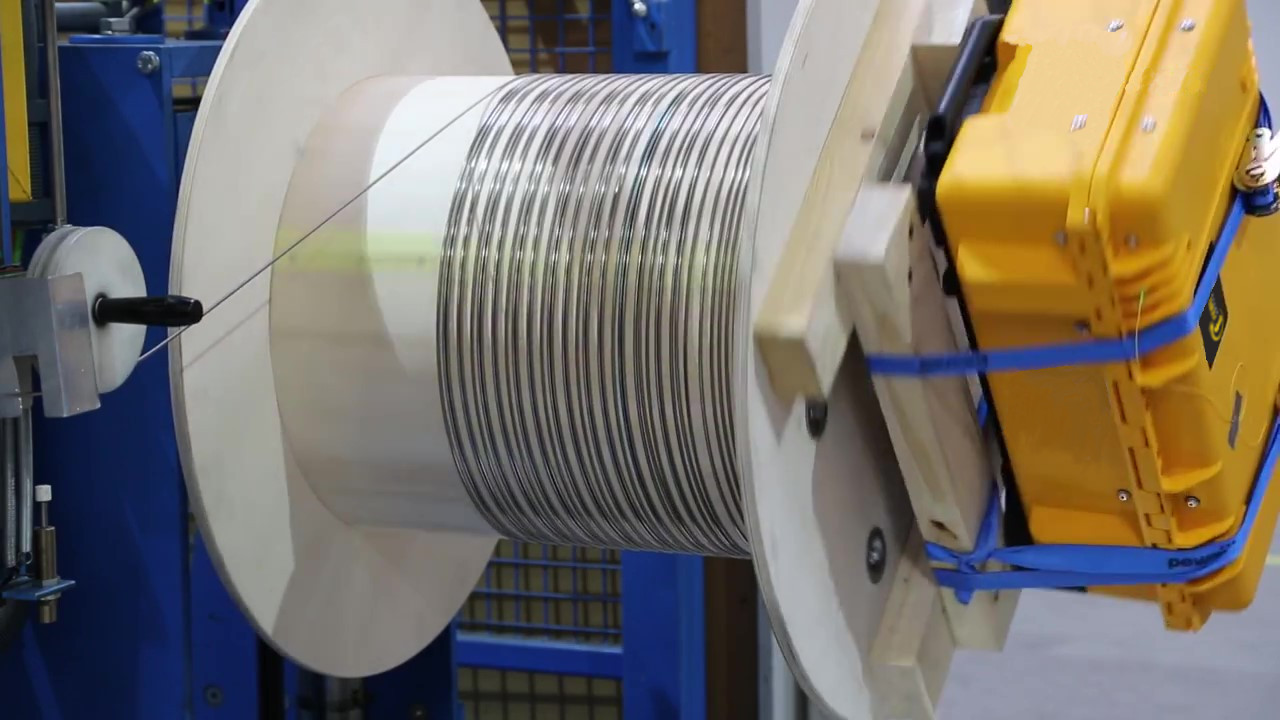

The FEBUS G1-C resists to harsh conditions and is dustproof and splashproof. Optimized to run when its rolling case is closed, it is compatible with many acquisition configurations. For example, it can be fixed to a rotary carousel or a reel and operates while moving.

The device has also been equipped with a Wifi connection allowing you to work remotely or to control the equipment via a laptop while the equipment is monitoring an asset near by.

The FEBUS G1-C can drive measurements on several optical fibers with up to 4 channels. Entirely “plug and work”, the user also takes advantage of its speed up to 1 Hz per channel.

This interrogator finally gives the opportunity to reduce customer equipment investments and maintenance costs. Indeed, distributed fiber optic sensing is often performed on long-distance infrastructures.

The FEBUS G1-C offers a range up to 50 km and can be connected to our REM (Range Extender Module) reducing the need for additional interrogators.

The FEBUS Optics service

FEBUS Optics’ teams ensure a support and are at their customers service during the different steps of each project.

- Factory Acceptance Tests (FAT) / Integrated Factory Acceptance Tests (IFAT): FEBUS Optics achieves quality checks on its devices according to the IEC 61757-2-2 standards. We provide documents as the functional design specification and take charge of the entire organization of a FAT.

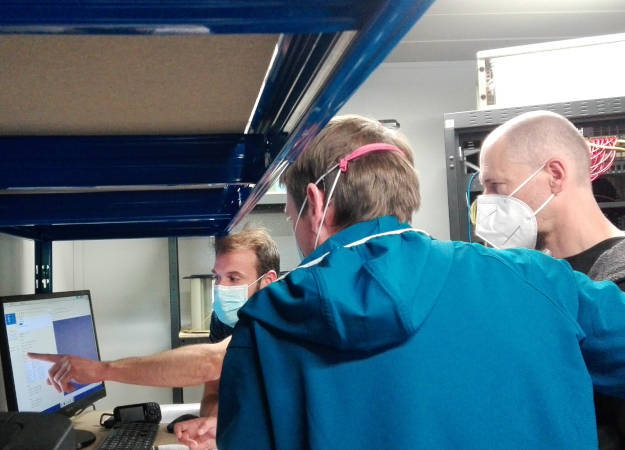

- Installation commissioning: the FEBUS Optics’ teams and its partners worldwide come on site to achieve the interrogator implementation including spatial calibration.

- Training: FEBUS Optics’ experts provide a training program and ensure a support during the entire operation.

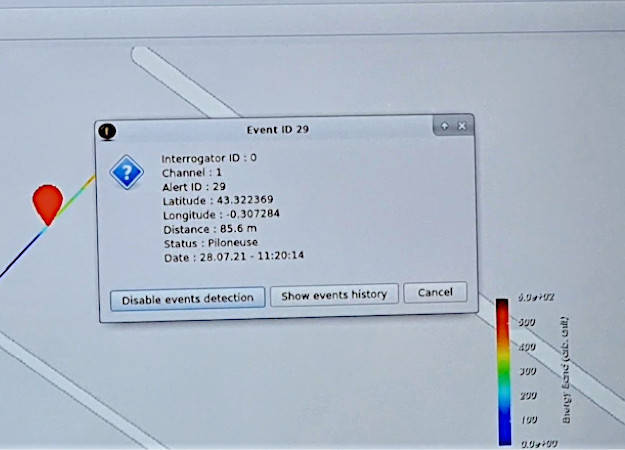

- Site Acceptance Tests (SAT): FEBUS Optics’ field engineers are highly experienced to propose and perform site acceptance procedures for many applications (pipeline leak detection, intrusion detection…).

- Warranty & maintenance: our interrogators are two-year guaranteed (parts and labor). On-demand, we also offer maintenance plan including remote, on site, factory maintenance, upgrade or repair.